A key discovery in the future of plastics: Kyoto University develops original technique to successfully blend polymers

July 2, 2015

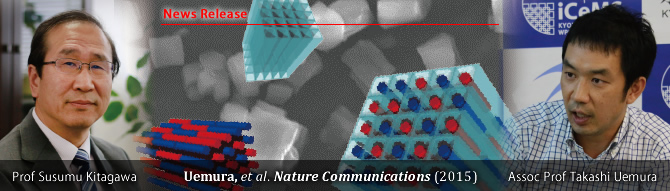

A team of researchers led by Dr. Susumu Kitagawa at Kyoto University's groundbreaking Institute for Integrated Cell-Material Sciences (iCeMS) has developed a new technique to successfully blend different types of polymers for the first time. This finding, published on July 1st in Nature Communications, will significantly contribute to the development of novel smart materials.

Polymers have important roles in many industries in the form of plastics and fibers and are used in everything from car tires, electronics to blood dialysis membranes.

However, as 1974 Nobel Prize-winning chemist Paul J. Flory revealed, blending polymers together to form so-called 'polymer alloys' at the molecular level has so far been almost impossible.

Previous methods of polymer blending have historically only yielded poor results, forming segregated polymer domains, and this has been a significant barrier to producing many scientifically and technologically useful materials, the advanced plastics of the future. Until now.

By taking a fundamentally different approach, iCeMS scientists have made a discovery that makes the homogeneous mixing of chemically immiscible substances a reality.

The team adopted a templating approach, building what may be imagined as 'removable scaffolding' using materials called porous coordination polymers (PCPs). These microscopic materials have numerous pores and a climbing-frame structure which functions as a kind of frame within which two polymers may blend together under chemical treatment. Once the process is complete the PCPs are removed, much as workmen remove the supports once a building is complete.

Using this new technique the iCeMS group succeeded in blending polystyrene and poly(methyl methacrylate), better known as PMMA, at the molecular level. Polystyrene is renowned for its strength, light weight and low cost. PMMA, commonly referred to by the trade names 'Perspex' and 'Plexiglass', has myriad applications from medical implants to aquarium windows to the exterior lights of automobiles. The resulting 'plastic alloy' will retain the properties of both.

"Our technique results in the ultimate blend," explains key researcher Takashi Uemura, of Kyoto University's Graduate School of Engineering. "It is a quick and very cost-effective procedure. This discovery will allow the development of a host of new blended polymers with applications across many industries. I am genuinely excited by this development in our field".

Publication Information

![]() Mixing of immiscible polymers using nanoporous coordination templates

Mixing of immiscible polymers using nanoporous coordination templates

Takashi Uemura1,2*, Tetsuya Kaseda1, Yotaro Sasaki1, Munehiro Inukai3, Takaaki Toriyama1,4, Atsushi Takahara4, Hiroshi Jinnai4,5, and Susumu Kitagawa1,3*

*Corresponding author

Nature Communications | Published Online 2 July 2015

DOI:10.1016/j.molcel.2015.05.015

- Department of Synthetic Chemistry and Biological Chemistry, Graduate School of Engineering, Kyoto University, Katsura, Nishikyo-ku, Kyoto 615-8510, Japan

- CREST, Japan Science and Technology Agency (JST), 4-1-8 Honcho, Kawaguchi, Saitama 332-0012, Japan

- Institute for Integrated Cell-Material Sciences (iCeMS), Kyoto University, Yoshida, Sakyo-ku, Kyoto 606-8501, Japan

- Institute of Materials Chemistry and Engineering (IMCE), Kyushu University, 744, Motooka, Nishi-ku, Fukuoka 819-0395, Japan

- Institute of Multidisciplinary Research for Advanced Materials (IMRAM), Tohoku University, 2-1-1, Katahira, Aoba-ku, Sendai 980-8577, Japan