A simple and versatile way to build three-dimensional materials of the future

October 16, 2014

Kyoto, Japan -- Researchers in Japan have developed a novel yet simple technique, called "diffusion driven layer-by-layer assembly," to construct graphene into porous three-dimensional (3D) structures for applications in devices such as batteries and supercapacitors. Their study was recently published in the journal Nature Communications.

Graphene is essentially an ultra-thin sheet of carbon and possesses exciting properties such as high mechanical stability and remarkable electrical conductivity. It has been touted as the next generation material that can conceivably revolutionize existing technology and energy sectors as we know them.

However, the thin structure of graphene also acts as a major obstacle for practical uses. When piecing together these tiny sheets into larger structures, the sheets easily stack with one another, resulting in a significant loss of unique material properties. While several strategies have been proposed to deal with this sticky issue, they are often costly, time consuming, and difficult to scale up.

To overcome this challenge, the researchers from the Institute for Integrated Cell-Material Sciences (iCeMS) at Kyoto University borrowed a principle from polymer chemistry and developed it into a technique to assemble graphene into porous 3D architectures while preventing stacking between the sheets. By putting graphene oxide (an oxidized form of graphene) into contact with an oppositely charged polymer, the two components could form a stable composite layer, a process also known as "interfacial complexation."

"Interestingly, the polymer could continuously diffuse through the interface and induce additional reactions, which allowed the graphene-based composite to develop into thick multi-layered structures. Hence, we named this process 'diffusion driven layer-by-layer assembly'," explained Jianli Zou, a co-investigator in the project.

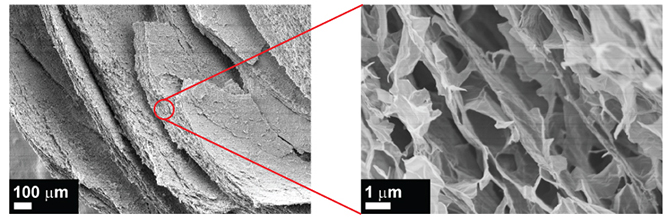

The resulting products display a foam-like porous structure, ideal for maximizing the benefits of graphene, with the porosity tunable from ultra-light to highly dense through simple changes in experimental conditions. Furthermore, the process is easily scalable for creating large-area films which will be highly useful as electrodes and membranes for energy generation or storage.

"While we have only demonstrated the construction of graphene-based structures in this study, we strongly believe that the new technique will be able to serve as a general method for the assembly of a much wider range of nanomaterials," concluded Franklin Kim, the principal investigator of the study.

Electron microscopy images of the porous graphene-based structure created by diffusion driven layer-by-layer assembly

Publication Information

![]() Diffusion-driven layer-by-layer assembly

of graphene oxide nanosheets into porous three-dimensional macrostructures

Diffusion-driven layer-by-layer assembly

of graphene oxide nanosheets into porous three-dimensional macrostructures

Jianli Zou1, Franklin Kim1

Nature Communications | Published Online 16 October 2014 | DOI: 10.1038/ncomms6254

- Institute for Integrated Cell-Material Sciences (iCeMS), Kyoto University, Kyoto 606-8501, Japan.

Media Coverage

- Materials 360

Scalable New Method Yields Porous Three-Dimensional Macrostructures (November 10, 2014, UK)

Scalable New Method Yields Porous Three-Dimensional Macrostructures (November 10, 2014, UK) - Nanotech Japan

Novel synthesis and development of a porous 3-dimensional graphene nanosheet consisting of carbon material that freely changes shape and pore size (October 27, 2014, Japan)

Novel synthesis and development of a porous 3-dimensional graphene nanosheet consisting of carbon material that freely changes shape and pore size (October 27, 2014, Japan) - Materials Today

Building 3D graphene structures layer by layer (October 22, 2014, UK)

Building 3D graphene structures layer by layer (October 22, 2014, UK) - Mirian

Simple and versatile way to build 3-dimensional materials of the future (October 22, 2014, Korea)

Simple and versatile way to build 3-dimensional materials of the future (October 22, 2014, Korea) - The Engineer

Graphene formed into porous 3D structures for use in batteries (October 22, 2014, UK)

Graphene formed into porous 3D structures for use in batteries (October 22, 2014, UK) - Le Scienze

How to produce 3-dimensional graphene (October 21, 2014, Italy)

How to produce 3-dimensional graphene (October 21, 2014, Italy) - Kurzweil

How to build layered 3D graphene-based materials (October 17, 2014)

How to build layered 3D graphene-based materials (October 17, 2014) - Global Brands

A Simple and Versatile way to build Three-Dimensional Materials of the Future (October 17, 2014, UK)

A Simple and Versatile way to build Three-Dimensional Materials of the Future (October 17, 2014, UK) - Science and Enterprise

Simple 3-D Graphene Construction Process Devised(October 17, 2014)

Simple 3-D Graphene Construction Process Devised(October 17, 2014) - Nanowerk

Controlling the size and shape of graphene-based multilayer structures(October 16, 2014, USA and Germany)

Controlling the size and shape of graphene-based multilayer structures(October 16, 2014, USA and Germany) - Phys Org

A simple and versatile way to build 3-dimensional materials of the futures(October 16, 2014, UK)

A simple and versatile way to build 3-dimensional materials of the futures(October 16, 2014, UK) - Product Design & Development

Building 3D Materials of the Future(October 16, 2014, USA)

Building 3D Materials of the Future(October 16, 2014, USA) - Machines like us

A simple and versatile way to build 3-dimensional materials of the future(October 16, 2014)

A simple and versatile way to build 3-dimensional materials of the future(October 16, 2014) - Science Daily

Simple and versatile way to build 3-D materials of the future(October 16, 2014, USA)

Simple and versatile way to build 3-D materials of the future(October 16, 2014, USA) - R&D

A simple and versatile way ot biuild three-dimensional materials of the future(October 16, 2014, USA)

A simple and versatile way ot biuild three-dimensional materials of the future(October 16, 2014, USA) - Science Codex

A simple and versatile way to build 3-dimensional materials of the future(October 16, 2014)

A simple and versatile way to build 3-dimensional materials of the future(October 16, 2014) - ECN

Building the 3-dimensional materials of the future(October 16, 2014, USA)

Building the 3-dimensional materials of the future(October 16, 2014, USA) - Printed Electronics World

Simple and versatile way to build three-dimensional materials(October 17, 2014, UK)

Simple and versatile way to build three-dimensional materials(October 17, 2014, UK) - World Industrial Reporter

Kyoto Devises Versatile Way to Build 3D Materials of the Future(October 16, 2014, USA)

Kyoto Devises Versatile Way to Build 3D Materials of the Future(October 16, 2014, USA) - Health Medicine Network

A simple and versatile way to build 3-dimensional materials of the future(October 16, 2014)

A simple and versatile way to build 3-dimensional materials of the future(October 16, 2014) - TG Techno

A simple and versatile way to build three-dimensional materials of the future(October 16, 2014, UK)

A simple and versatile way to build three-dimensional materials of the future(October 16, 2014, UK) - Brightsurf

A simple and versatile way to build 3-dimensional materials of the future(October 16, 2014)

A simple and versatile way to build 3-dimensional materials of the future(October 16, 2014) - Nauka24

Japanese engineers have developed builk graphene structures(October 16, 2014, Russia)

Japanese engineers have developed builk graphene structures(October 16, 2014, Russia) - Info Hightech

A simple and versatile way of building materials of the future in 3D(October 17, 2014, France)

A simple and versatile way of building materials of the future in 3D(October 17, 2014, France)