Learning how to fine-tune nanofabrication

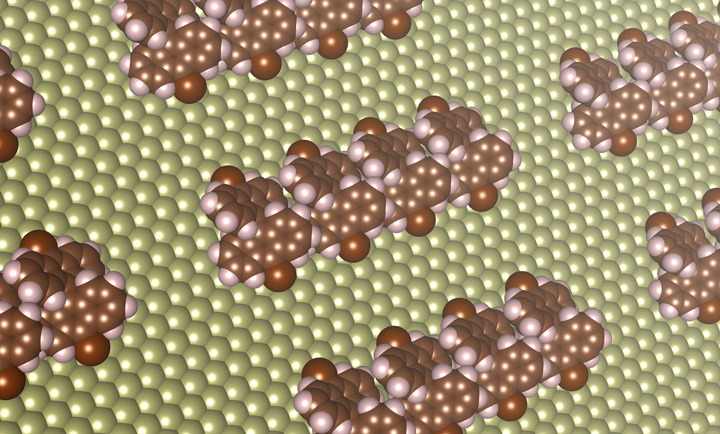

A new computational method may improve the control of nanomaterial fabrication.

Daniel Packwood, Junior Associate Professor at Kyoto University’s Institute for Integrated Cell-Material Sciences (iCeMS), is improving methods for constructing tiny “nanomaterials” using a “bottom-up” approach called “molecular self-assembly”. Using this method, molecules are chosen according to their ability to spontaneously interact and combine to form shapes with specific functions. In the future, this method may be used to produce tiny wires with diameters 1/100,000th that of a piece of hair, or tiny electrical circuits that can fit on the tip of a needle.

This research was published online on February 14, 2017 in Nature Communications

Further details are available at the following page:

Kyoto University | Learning how to fine-tune nanofabrication