Designing Flexible Porous Materials with Phase-Transformable MOPs

Principal Engineer at Taiwan Semiconductor Manufacturing Company, Ltd.

A doctoral student at National Taiwan University and a Guest Research Associate at iCeMS Furukawa Lab, at the time of this research.

Po-Chun Han

Po-Chun Han

Mr Po-Chun Han was a student from National Taiwan University, visiting Professor Furukawa’s lab at iCeMS as a Guest Research Associate. He was committed to developing innovative microporous materials for chemical engineering applications. In collaboration with his partners at iCeMS and in Taiwan, he built a phase-transformable membrane based on metal-organic polyhedra (MOPs) for CO₂/H₂ gas separation.

Please share with us the significance of your manuscript in terms of its research achievements, impact, or uniqueness.

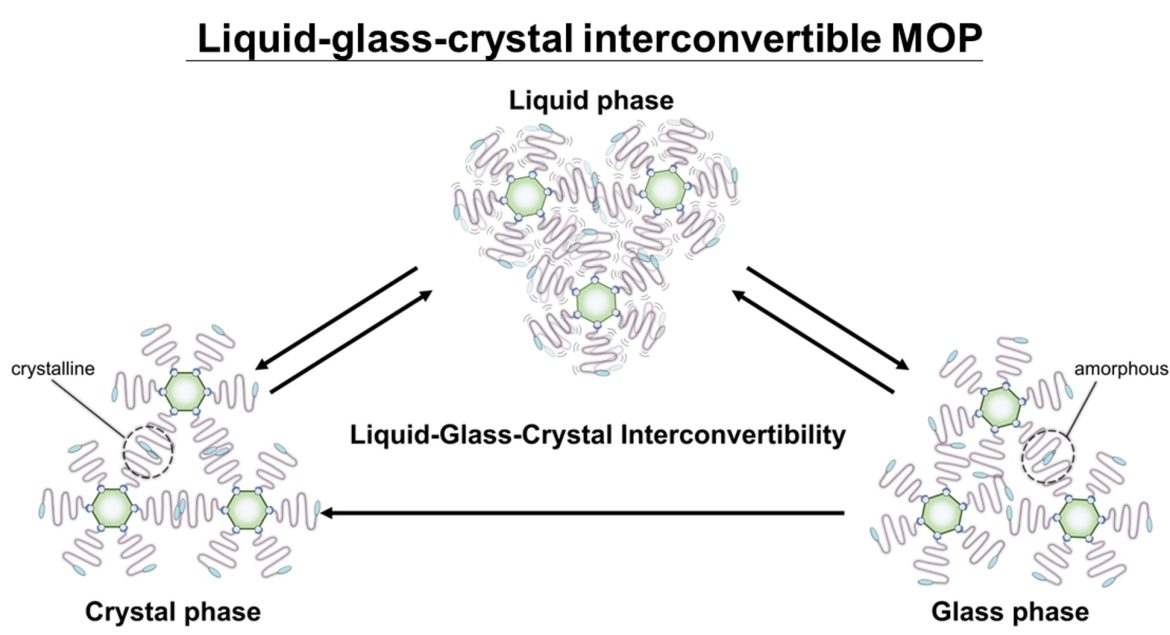

The rigidity of conventional microporous materials limits their ability to transition between different physical states, reducing their adaptability for various industrial applications. However, efforts to improve the processability of microporous materials often lead to a partial or complete loss of porosity during the transformation process. This work presents the phase-transformable metal-organic polyhedra (MOPs) that can reversibly switch between liquid, glass, and crystal phases while maintaining intrinsic microporosity. The key to this innovation lies in a modular synthetic approach, where molecular MOPs serve as inherently porous hosts and phase-transformable polymeric chains are tethered on the surface of MOPs via coordination bonds, resulting in star polymer-like systems. By simply pressing liquid-state MOPs onto a porous substrate, we can create a membrane with tunable CO₂/H₂ selectivity, which can be adjusted by modifying the physical state of the MOPs through heat treatment. This research enables the design of advanced porous materials that combine high tunability with enhanced processability to address complicated scenarios in industrial settings.

Please tell us what was the most gratifying or inspiring moment for you during this research project.

The first time I saw a droplet of MOPs appear in front of me is truly unforgettable.

Since all the fundamental components for creating liquid-state MOPs exist as solids at ambient temperature, I had always been accustomed to obtaining only solid-state products in my experiments. But when it finally happened—when that droplet formed—I knew instantly: this is it! Seeing MOPs transition into a liquid and witnessing how the coordination reaction altered their physical state was the most inspiring moment in my research journey.

Please tell us about the biggest challenge or problem you experienced while conducting your research. How did you overcome it?

The biggest challenge was the synthesis approach of the polymers. At the beginning of this project, I had determined the polymer design but struggled to find a suitable precursor to synthesize it. That changed when I shared my preliminary results with Dr. Alexandre Legrand, who has extensive experience with various chemicals used to create porous liquids in Furukawa’s group. He introduced me to a chemical named Triton X, a family of nonionic surfactants with a hydroxyl group at one end and a bulky tert-octylphenyl group at the other end. Its structure provided a solution, allowing me to obtain the desired polymer without encountering selectivity issues in the synthesis route. Finally, the polymers were successfully synthesized and given rise to the liquid state MOPs.

Would you consider this work to be a turning point in your overall research direction? If so, how has your research direction changed as a result of this work?

Certainly, this work marks a turning point in my career. During the first few years of PhD career, I never had the opportunity to develop new materials. Instead, I worked extensively with well-studied materials for innovative applications. However, this project allowed me to develop new types of materials with unique properties that other researchers might find useful in specific fields in the future. After this experience, I’m more interested in designing innovative materials. Although the process of creating new things is challenging, exploring an unknown region itself is beyond satisfying.

Please describe the current situation of your career. What is your current position? How has the knowledge and experience gained at iCeMS influencing your career?

After completing my PhD at National Taiwan University, I am now working as a principal engineer at Taiwan Semiconductor Manufacturing Company. My experience at iCeMS gives me a lot of aid when I try to summarize my work to others. Prof. Furukawa has been a great model for me. He consistently seeks the root cause behind the phenomena through scientific evidence and skillfully integrates numerous factors into a clear and logical story. Although there’s still a large space I can improve, the skills I gained in iCeMS does help me deal with complicated engineering problems and presentations.

Finally, please give a message or advice to young iCeMS researchers.

As a former visiting student, I highly recommend iCeMS to anyone passionate about cutting-edge materials. The institute brings together young talents and experienced researchers to push the boundaries of material science, all while being immersed in Kyoto’s rich historical atmosphere.

Paper information

"Phase-transformable metal-organic polyhedra for membrane processing and switchable gas separation"

Authors: Po-Chun Han, Chia-Hui Chuang, Shang-Wei Lin, Xiangmei Xiang, Zaoming Wang, Mako Kuzumoto, Shun Tokuda, Tomoki Tateishi, Alexandre Legrand, Min Ying Tsang, Hsiao-Ching Yang, Kevin C.-W. Wu, Kenji Urayama, Dun-Yen Kang, Shuhei Furukawa

Published: November 2024